Non-return/Solenoid valves work by using an electrically

activated solenoid to control the flow of fluid through the valve. When the

solenoid is energized, a magnetic field is created, pulling the valve plunger

into the valve body, opening the flow path. When the solenoid is de-energized,

a spring in the valve pushes the plunger back into its original position,

closing the path again.

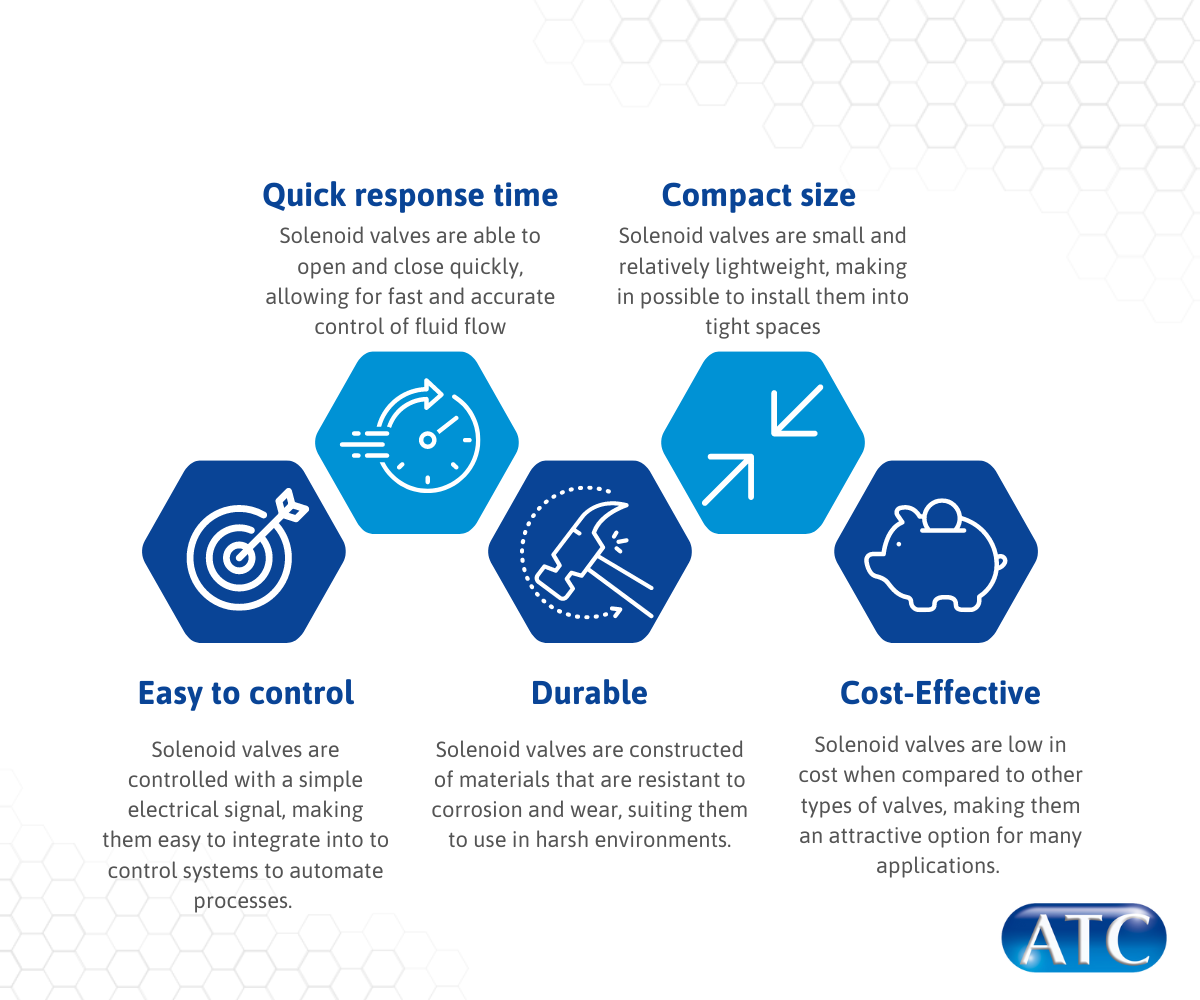

The use of solenoid valves can offer several benefits,

including:

Quick response time

Solenoid valves are able to open and close

quickly, allowing for fast and accurate control of fluid flow, making them

well-suited for use in process cooling systems where precise temperature

control is required.

Easy to control

Solenoid valves are controlled with a simple

electrical signal, making them easy to integrate into to control systems to

automate processes.

Compact size

Solenoid valves are small and relatively

lightweight, making in possible to install them into tight spaces or systems

that have limited room available for components.

Durable

Solenoid valves are constructed of materials

that are resistant to corrosion and wear, suiting them to use in harsh

environments.

Cost-effective

Solenoid valves are low in cost when compared to

other types of valves, making them an attractive option for many applications.

While solenoid valves offer many advantages when used in

process cooling equipment, there are also some drawbacks to consider:

Electrical dependence

- Solenoid valves rely on an electrical current to

operate, which means that they are not suitable for use in applications where

there is no electrical power available. If the electrical power is disrupted or

fails, the valve may not operate as intended.

Limited flow control

- Whilst

solenoid valves are able to open and close quickly, they are not typically

designed with fine flow control in mind. If precise control of fluid flow is

required, additional measures may be required.

Limited pressure range

- Solenoid

valves are designed for use at low to medium pressures, but may not be suitable

under high pressures.

Maintenance requirements

- As with any component, solenoid valves may be

subject to wear and tear, and may require replacement over time. If exposed to

high temperatures or corrosive fluids, the solenoid coil can become damaged.

When used in process cooling equipment, solenoid valves are

often used in conjunction with other components such as temperature sensors,

flow meters, and control systems to ensure efficient and accurate control.

Solenoid valves are often fitted to prevent back siphoning

of fluid into the chiller when it is turned off for refilling or maintenance.

They are recommended when the chiller and application are at

different levels (more than 2 meters height difference), or where a long length

of flexible tubing is used between the chiller and the application. It is also

advisable to add non-return/solenoid valves in situations where pipe-runs will

be going up into ceiling ducts.