Product Series - Airblast Coolers

Airblast coolers use ambient air to

maintain the temperature of process fluids, without the use of refrigeration

system. In simple terms, this is achieved by forcing air over the process

fluids to remove unwanted heat and ejecting it into the environment.

How does an Airblast Cooler Work?

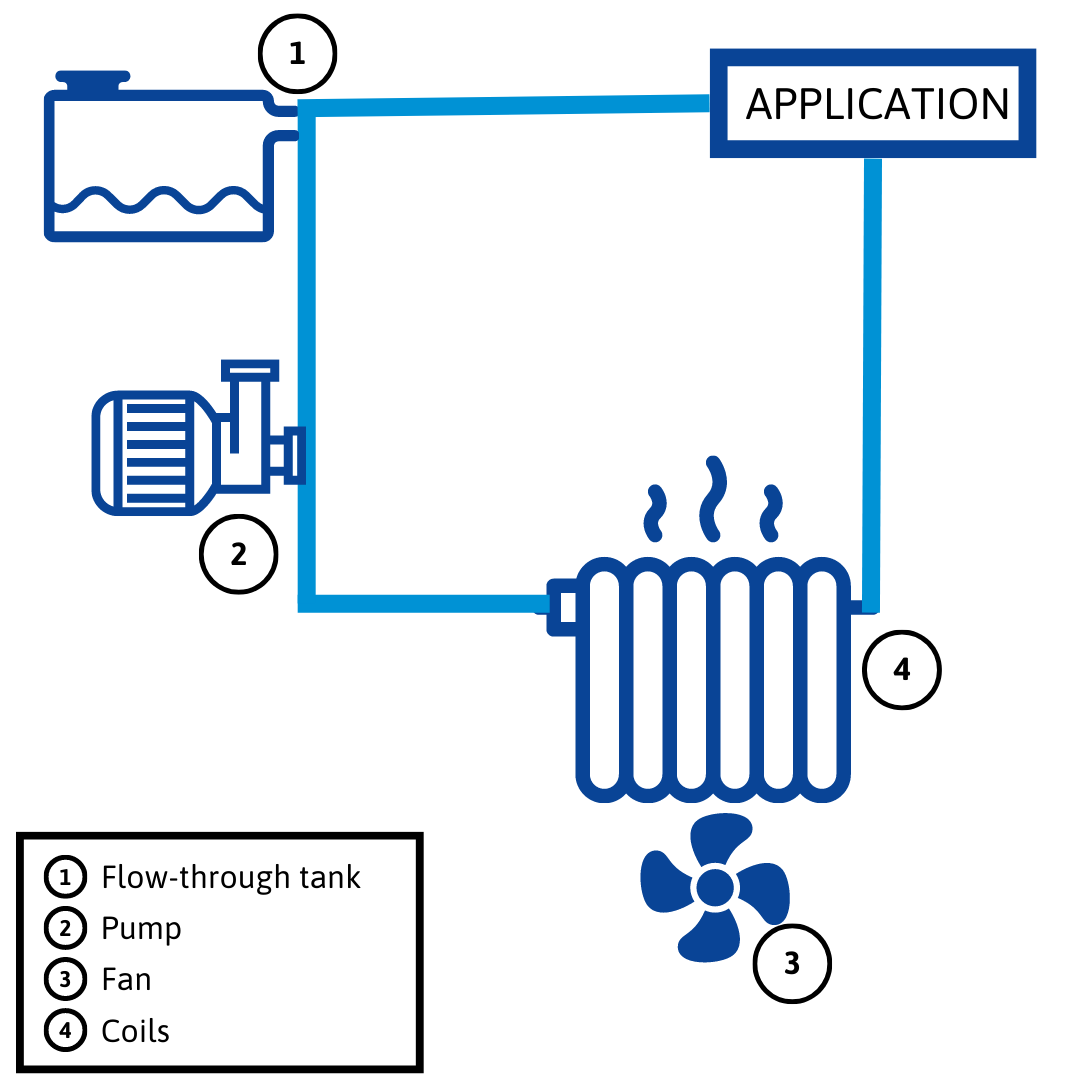

Airblast coolers pump

fluid around your application to maintain the desired temperature. The fluid

leaves the outlet of the cooler and is pumped through the application. Heat is

absorbed into the fluid from the application and returns to the chiller through

the inlet and into the tank. This helps to buffer the temperature. From the

tank the fluid is drawn down through the pump and then through the water to air

heat exchanger. In the heat exchanger, air is pulled across the fluid and heat

is ejected to air. The fluid then repeats its journey through the application.

Following this process, temperatures can be as low as 10°C above ambient

temperature.

Unlike chillers, Airblast

coolers do not have compressors, so are not constrained by the same operating conditions.

Chillers must feature a high pressure/high temperature cut off switch to

protect the chiller (and compressor) in high ambient temperature conditions.

This issue can be worsened where chillers are kept outside as they are affected

by sunlight. The upper limit of an Airblast cooler’s operating conditions is

only defined by the heat transfer fluid used and the thermal properties of the

water circuit materials, allowing them to operate efficiently in warmer

environments.

How are Different Coolants Used in Airblast Coolers?

Process fluids commonly

used with Airblast coolers include water, glycol, and oils. Process fluids are

often known as heat transfer fluids.

Water

Water can be used as a

heat transfer fluid, meeting the needs of most liquid-cooling applications.

Water is cheaply available, non-toxic and has a high thermal capacity. It has

low viscosity, making it easy to pump. However, water has a low boiling

temperature and freezes easily, making it unstable and difficult to manage at

extreme temperatures. De-ionised water may be considered for use with sensitive

applications, as water with a high mineral substance can cause deposits in the

system plumbing, and a pH level that is too acidic/alkaline can be destructive.

Water alone has no antimicrobial properties, leaving the system vulnerable to

contamination – an issue that can be costly, and time consuming to remedy.

Glycol

Glycol/water combinations

may be used as a heat transfer fluid. When added to water, glycol prevents

fluids from freezing, allowing applications to operate at much lower

temperatures than when using water alone as a heat transfer fluid. The addition

of glycol has a lubricating effect on the pump, allowing the system to run

smoothly. In comparison to water, water/glycol solutions can be more difficult

to clean up in the event of a spillage due to its high boiling point and

viscosity.

Ethylene Glycol/water

combinations, such as Coolflow, are relatively inexpensive but must be replaced

every 5 years to guarantee optimum performance.

Applied Thermal Control are the exclusive supplier of Hexid,

a propylene glycol/water combination. Hexid is biodegradable and non-toxic,

making it a more environmentally friendly choice of heat transfer fluid. It

also contains a trace biocide, which will stop any microbial contamination

within the system. Hexid must be changed yearly but is easy and safe to dispose

of.

Oils

Oils are frequently used with Airblast coolers. They have a higher

liquid temperature than water, so it is unlikely that viscosity will present as

an issue with the temperatures achieved through this cooling process. However,

oils may require more energy to pump around the system than a less viscous

counterpart. Due to this, special pumps may be required when using oils as heat

transfer fluids.

What Different Control Methods are Available?

ATC house all Airblast

coolers in robust steel enclosures, providing any exposed electrical parts

exposed to the weather with an IP54 rating, meaning that they are protected

against dust and water splashed from all directions. As Airblast coolers are

not affected by sunlight, they can be kept outside without weather conditions

affecting performance.

By default, the fans in

ATC Airblast coolers are permanently working. If you are concerned about noise

or would like closer or more stable temperature control, ATC have two different

option packs available: on/off and proportional control.

The on/off fan speed control pack allows the fan to turn off when not

needed. As the fan blades of an Airblast cooler cut through air, they can

generate a high-pitched noise. This pack can be helpful in residential areas,

turning the fan off at night to reduce noise levels

The addition of a proportional fan speed control pack allows the fan to

adjust to meet the needs of the cooling process, by means of an analogue signal

with an inverter which is able to simulate a low power supply. Proportional fan

speed control can help to make Airblast coolers more environmentally friendly,

with a reduction in noise levels and energy consumption.

When running an Airblast

cooler in a high ambient environment (typically an environment over 35°C), a

high ambient fan can be fitted, allowing the fans to run at double the motor

speed, from 1250RPM to 2500RPM. A proportional fan speed controller can be

fitted with this option to overcome any issues with low ambient temperatures,

at night for example. High ambient fans can also be repurposed to increase cooling

capacity by up to 30%.

Where the application

requires process fluids to increase in temperature, or remain at a maintained

temperature, ATC offer a heater pack as a standard option.

Non-return solenoid valves

can be fitted to Applied Thermal Control’s range of Airblast coolers, preventing any backflow of fluid into the system when not operational, for

example, when fans are not running. This option is particularly relevant to

coolers being installed at a different height (over 2 meters difference) to the

application, or where long lengths of tubing is used to connect the two.

Volt Free Connections can

be installed to allow monitoring of alarms through analogue communication

between the Airblast cooler and application. This standard option allows flow,

temperature, level and all-OK VCF’s to be communicated. A remote stop/start can

also be fitted, allowing the cooler to be shut down remotely in the event that

an alarm sounds.

Applied Thermal Control

supply filter kits as a standard option, which can be beneficial to Airblast

coolers, considering the industrial environments within which they frequently

operate. The addition of a particulate filter can protect either the

application, or the cooler. Further details on this can be found here.

Airblast Cooling at Applied Thermal Control

Thermal Exchange were founded in 1982, initially to provide a reliable,

UK based supplier of Airblast coolers into the metal fabrication industry. In

2019, when the SDI Group acquired Thermal Exchange, merging them with ATC at

a new site in Barrow upon Soar. Thermal Exchange specialised in Airblast

coolers, often used in the welding industry, which could be customised to the

bespoke requirements of the end user. The merge between ATC and Thermal

Exchange allowed for technical knowledge and expertise to be enhanced by the

sharing of experience and insight, resulting in a greater choice of cooling

solutions available to customers. This has also allowed for improved on-site

service and maintenance options, reducing downtime.

Applied Thermal Control now offer the

A-series – a compact and transportable range of Airblast coolers designed to

control the temperature of water, glycols and oils to support a wide range of

applications.

Products in the A-series range are simple

and easy to operate and maintain. All Airblast coolers within the range feature

a pressure gauge, a temperature gauge, and a visual tank level indicator,

allowing the user to perform visual checks with ease. Circuit breakers, on/off

switch, and coolant safety by-pass are also fitted as standard.