Temperature control in process cooling typically involves

the use of a temperature control system.

Applied Thermal Control use Proportional-Integral-Derivative

(PID) control in the design of our recirculating chillers (aside from the

ecoMini). PID is a more advanced form of feedback control that uses a

mathematical algorithm to optimise temperature control. The algorithm takes

into account the current temperature, the rate of change in temperature, and

the accumulated error over time to determine the optimal cooling rate.

PID control is a closed-loop system that uses feedback from

the process being controlled to make adjustments to the control system. It

works by calculating the difference between the desired output (setpoint) and

the actual output and using this error information to make corrections to the

control system.

The correction is made up of three components:

This component of the correction is proportional

to the size of the error. If the error is large, the correction is also large.

If the error is small, so is the correction. The proportional control component

helps to bring the process variable towards the setpoint quickly.

This component of the correction is based on the

accumulated error over time. It helps to eliminate any persistent error that

may remain after the proportional control component has been applied.

This component of the correction is based on the

rate of change of the process variable. It helps to anticipate and prevent

overshoots in the process variable.

These components are combined and applied to the control

system to produce a correction that optimises the control of the process.

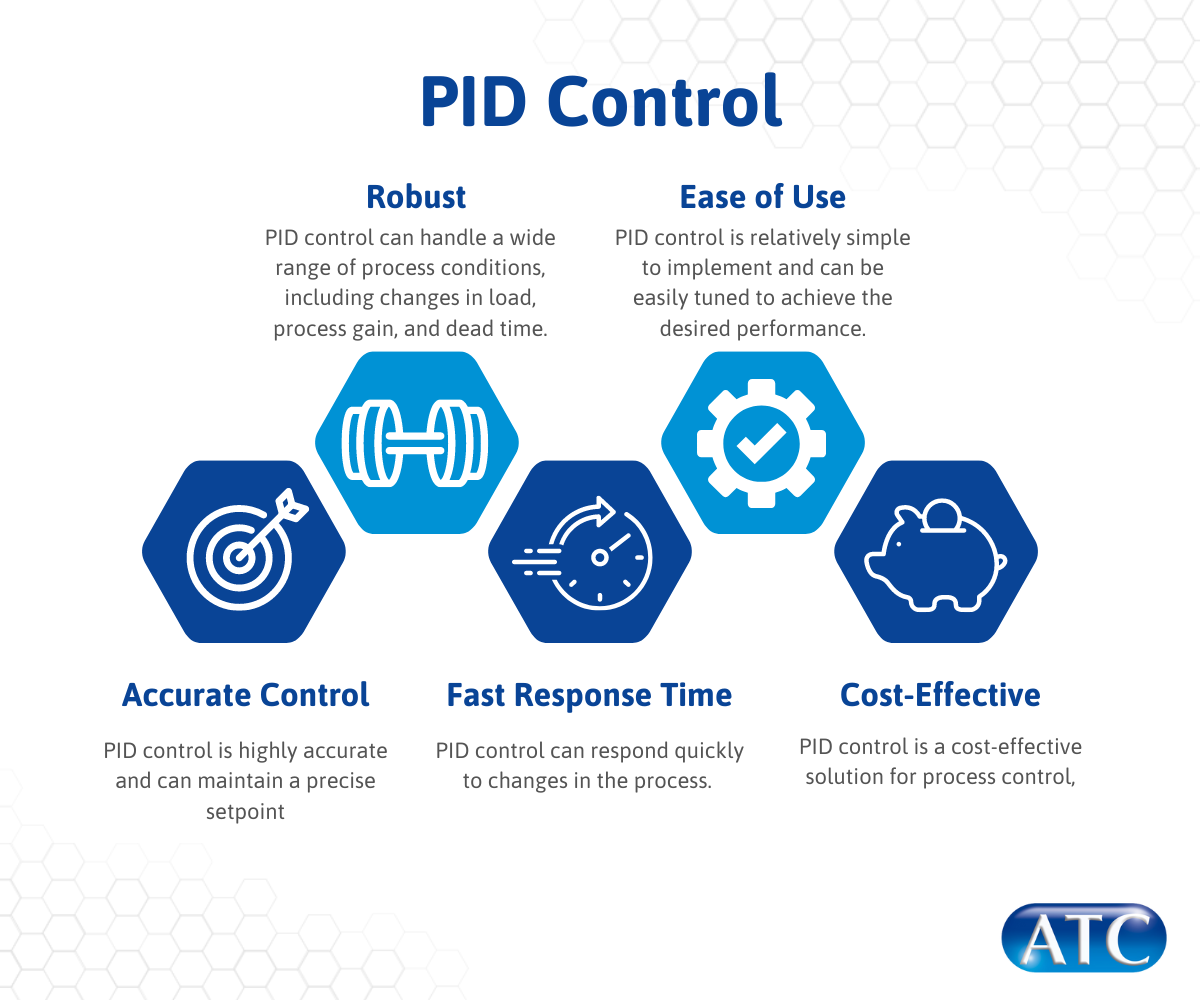

The benefits of using PID include:

- Accurate control - PID control is highly accurate and can maintain

a precise setpoint, even in the presence of disturbances or changes in the

process. This makes it ideal for applications where precise control is

required.

- Fast response time - PID control can respond

quickly to changes in the process, which is important in applications where

fast response times are required.

- Robustness - PID control is highly robust, and can handle a

wide range of process conditions, including changes in load, process gain, and

dead time. This makes it a good choice for applications where the process

conditions are subject to change.

- Ease of use - PID control is relatively simple to implement

and can be easily tuned to achieve the desired performance. This ease of use

makes it a popular choice for process control.

- Cost-effective - PID control is a cost-effective solution for

process control, especially when compared with more complex control systems.