A recirculating chiller is a system composed of two main

loops or circuits:

- The refrigerant circuit

- The coolant circuit

The refrigeration circuit is the sub-system within the

chiller that provides the cooling engine. It is within this circuit that thermodynamic

processes occur.

The water circuit is where heat transfer occurs and is a

distribution system for heat transfer fluids.

The Refrigeration Circuit

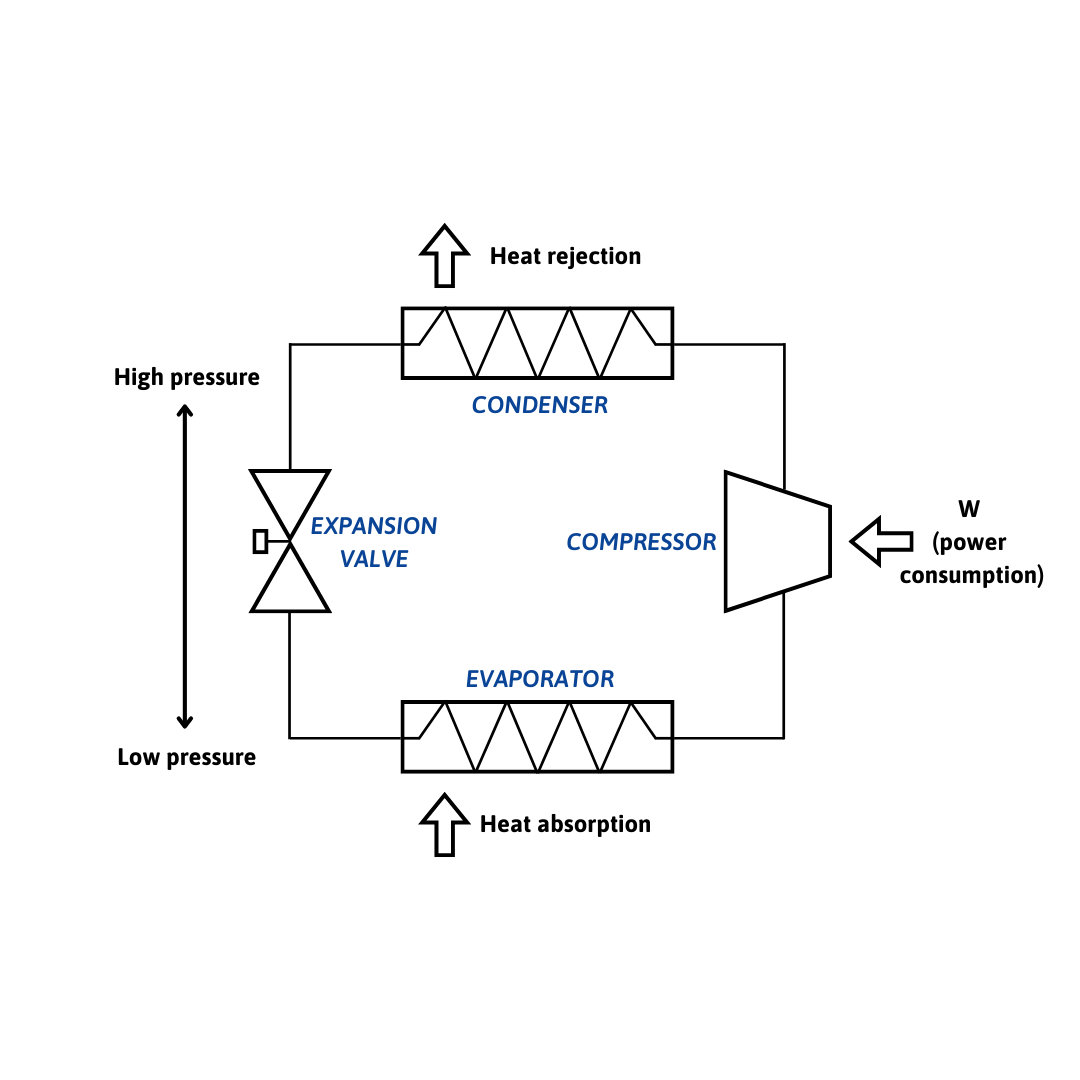

The refrigeration circuit in a recirculating chiller works

under the principle of a vapour compression cycle. Moving through the cycle,

the refrigerant changes from gas to liquid, and returns to gas again. The

stages of this cycle are explained below:

Compression

At the start of the cycle, the refrigerant is in a low-pressure

vapour state, carrying heat absorbed from the evaporator. At this stage, the

refrigerant is at the same temperature as the ambient air or environment.

The compressor pressurises the vapourised refrigerant by

expending mechanical energy, which is then discharged to the high-pressure side

of the system. When under high pressure, the temperature of the refrigerant

becomes higher than the temperature of the ambient air or environment.

Condensation

The condenser is in the high side of the refrigeration

circuit and is a heat exchanger used to transfer heat from the refrigerant to

the environment. Due to the thermal gradient existing between the refrigerant

and the environment, heat transfer is able to take place and both heat absorbed

by the evaporator and heat generated by the compressor are discharged. The

environment acts as a heat sink, absorbing the rejected heat. In recirculating

chillers, this ‘environment’ is the water circuit.

As the refrigerant is cooled within the condenser it returns

to a liquid state.

Expansion

To begin with the liquid refrigerant is in a high-pressure

state with the same temperature as the ambient environment. Expansion is

usually achieved by passing the refrigerant through an expansion device such as

a thermal expansion valve or capillary tube. During the expansion process, the

refrigerant lowers its pressure. As the pressure drops, as does the temperature

of the refrigerant. A small amount of refrigerant may flash, or turn into

vapour, further lowering the temperature of the refrigerant. In theory, this

process happens without the transfer of heat or energy.

Refrigerant then flows into the low-pressure side of the

system.

Evaporation

The evaporator is on the low-pressure side of the system.

Here, heat exchange between the refrigerant and the heat transfer fluid takes

place. The refrigerant absorbs heat from the heat transfer fluid, elevating the

temperature of the refrigerant until it vaporises. Following this process, the

refrigerant is in a low-pressure state with a temperature the same as the

ambient environment.

The refrigerant then flows into the compressor for the cycle

to start again.