0-15kW Rack Mounted Water to Water Heat Exchangers

The XR-Series is a range of 19” rack mountable water-to-water

heat exchangers, designed for use with primary water circuits, providing

cooling to applications for which the facilities water may be unsuitable. Water-to-water

heat exchangers can address water quality concerns, overcoming issues

associated with insufficient pressure, fluctuating flow, or very cold water, by

providing a stable supply of coolant to the process, regardless of facility

water condition, ensuring that processes remain at optimum performance. They

are also effective at protecting more sensitive equipment from microbial

contamination.

A water-to-water heat exchanger sits between the application

and the primary water circuit, modulating the flow rate to achieve temperature

stability without the need for a refrigeration circuit. They are ideal in situations

where the application set point is higher than the primary water supply, as the

set point does not need to be lower than the primary circuit temperature.

The XR-Series is a self-contained system, comprised of a

modulated primary supply, the water-to-water heat exchanger, and the coolant

storage tank. A wide range of non-ferrous/stainless steel pumps are available,

both positive displacement and centrifugal, with varying flows and pressures to

suit a multitude of requirements. All pumps have fan-cooled electric motors and

are supplied in 304 & 316 stainless steel as standard.

The XR-Series is suitable for use with a wide range of

fluids, including:

Features of the XR-Series include:

- Supplied complete with circuit breakers and on/off switches.

- Coolant pump starting contactors

- Pump motor protection

- IP54 protection.

- 24V control circuit available

- Temperature gauge

- Pressure gauge

- Coolant safety bypass

- Visual tank level indicator

Common applications include:

·

- Resistance Welding Machines

- High Frequency Generators

-

Furnace Equipment

- X-Ray Devices

- Lasers

- General Process Cooling

Floor standing variants

are available on request.

Download the full spec sheet

here | | | | | | | | |

Nominal capacity at 10'K

(i.e. return line 0'K above outlet)

(i.e. outlet 10'K above house supply) | | 4kW | | 8kW | | 15kW | |

| Administrative Data | | | | | | | |

| CAD assembly dwg no. | |

MA345 | |

MA345 | |

MA345 | |

| ATC new model name | | XR04059 | | XR08109 | | XR15179 | |

| | | | | | | | |

| Physical attributes | | | | | | | |

| Physical dimensions(mm) | | 19" rack, 5U high, 500mm deep | | 19" rack, 5U high, 500mm deep | | 19" rack, 5U high, 500mm deep | |

| Weight (kg) | | 30 | | 30 | | 30 | |

| Toolless access | | No | | No | | No | |

| | | | | | | | |

| Temperature control attributes | | | | | | | |

| Technology | | Water-to-water heat exchanger | | Water-to-water heat exchanger | | Water-to-water heat exchanger | |

| Temperature range (standard) | | +4°C to +70°C

| | +4°C to +70°C | | +4°C to +70°C | |

| Maximum return line temperature | | +65°C

| | +65°C | | +65°C | |

| Control method | | Modulating valve | | Modulating valve | | Modulating valve | |

| Temperature stability (with constant load) | | ±1°C

| | ±1°C | | ±1°C | |

| Settable temperature resolution | | 0.1°C | | 0.1°C | | 0.1°C | |

| | | | | | | | |

| Water circuit attributes | | | | | | | |

| System volume (L) | | 2.3 | | 2.3 | | 2.3 | |

| Pump Type | | 5L/min Rotary vane (PD)

| | 10L/min Rotary vane (PD) | | 17L/min Rotary vane (PD) | |

| Pump capability | | 6bar@5L/min | | 6bar@10L/min | | 6bar@17L/min

| |

| Pressure control (settable pressure relief valve) | | Internal, PRV, 20-150psi

| | Internal, PRV, 20-150psi | | Internal, PRV, 20-150psi | |

| Standard fittings | | 1/2" BSPPF | | 1/2" BSPPF | | 1/2" BSPPF | |

| Standard chemical compatibility | | Hexid Fluid, Water, Propylene Glycol | | Hexid Fluid, Water, Propylene Glycol | | Hexid Fluid, Water, Propylene Glycol | |

| | | | | | | | |

| Electrical attributes | | | | | | | |

| (208-230Vac, 1/2, 50/60Hz) 9-spec | | Yes, 4.5A

| | Yes, 4.5A | | Yes, 4.5A | |

| | | | | | | | |

| Safety and fault indicator | | | | | | | |

| 1st party approvals | | CE | | CE | | CE | |

3rd party approvals

| | UL-ready | | UL-ready | | UL-ready | |

| Empty fluid reservoir alarm | | Safety Interlock | | Safety Interlock | | Safety Interlock

| |

| Low fluid flow alarm | | Visual lamp | | Visual lamp | | Visual lamp

| |

| Temperature out of range alarm | | N/A | | N/A | | N/A

| |

| Motor thermal overload | | Standard | | Standard | | Standard

| |

| Emergency off | | Standard, via fuse | | Standard, via fuse | | Standard, via Fuse

| |

| Warranty options | | 2 year parts, 1 year labour | | 2 year parts, 1 year labour | | 2 year parts, 1 year labour

| |

| | | Enhanced warranty options | | Enhanced warranty options | | Enhanced warranty options

| |

| Interlock restored, restart mode | | Automatic | | Automatic | | Automatic

| |

| Overcurrent fault-cleared restart mode | | Manual | | Manual | | Manual | |

| | | | | | | | |

| Options available | | | | | | | |

| Remote alarm/power-off; SA00001 | |

N/A | |

N/A | |

N/A | |

| Low temperature pack; SA00002 | |

N/A | |

N/A | |

N/A | |

| High temperature pack; SA00003 | | Available, to +75°C | | Available, to +75°C | | Available, to +75°C

| |

| Water cooled KT; SA00004 | |

N/A | |

N/A | |

N/A | |

Water cooled K1; SA00005

| |

N/A | |

N/A | |

N/A | |

| Water cooled K4/K6/K9/K12; SA00006 | |

N/A | |

N/A | |

N/A | |

| Water cooled K3; SA00007 | |

N/A | |

N/A | |

N/A | |

| Non-return solenoid pack; SA00008 | | Available | | Available | | Available | |

| High temperature water circuit w/o heater; SA00009 | |

N/A | |

N/A | |

N/A | |

| Low flow alarm (KT); SA00010 | | Available | | Available | | Available | |

| Onboard RS485 data protocol; SA00011 | | N/A | | N/A | | Available | |

| Standard VFC set; SA00012 | | - | | - | | - | |

| In-line Deionising cartridge and fittings; SA00013 | | Available | | Available | | Available | |

Stainless non-return solenoid valve; SA00014

| | - | | - | | - | |

| Castors to replace rubber feet; SA00015 | | Available | | Available | | Available | |

| CPC quick release connectors; SA00016 | | Available | | Available | | Available

| |

| Installation kit; SA00017 | | Available | | Available | | Available | |

| Stainless steel pump and fittings; SA00018 | | -

| | - | | - | |

| KT filter kit; SA000019 | | - | | - | | - | |

| Mod for outdoor use; SA00020 | | - | | - | | - | |

| Particulate filter; SA00021 | | Available | | Available | | Available | |

Flow meter pack; SA00022

| | - | | - | | - | |

Fan speed control (on/off); SA00023

| |

Available | | Available | | Available | |

| Stainless enclosure; SA00029 | | Available | | Available | | Available | |

| | | | | | | | |

Please contact us for further details on this chiller range.

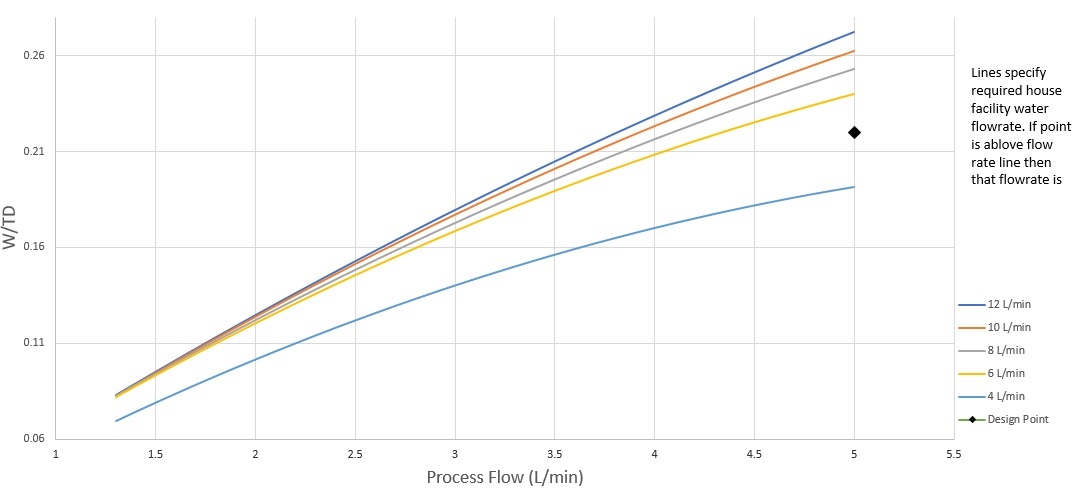

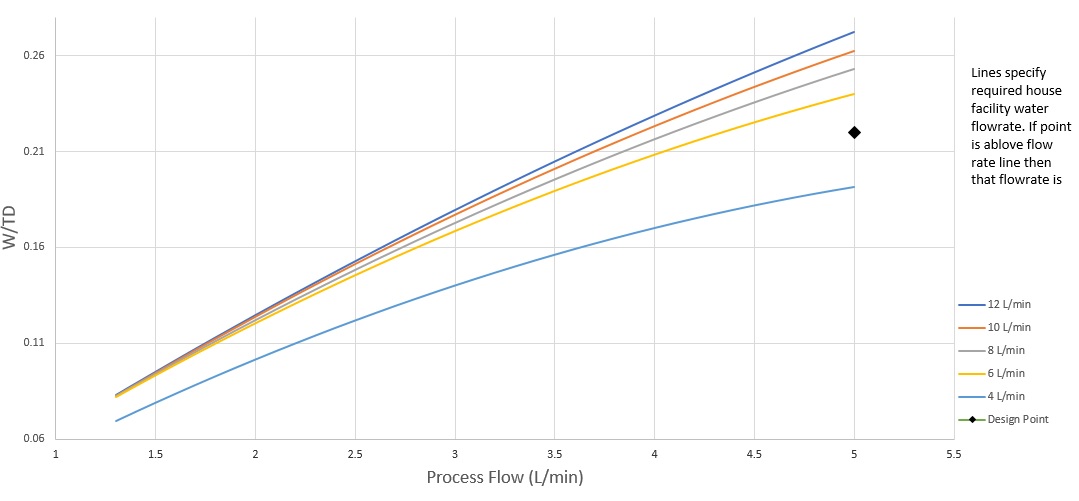

XR-Series Cooling Capacity

4kW Cooling Capacity

8kW Cooling Capacity